Explore our range of high-performance digital cutting solutions designed for versatility and precision.

L Series

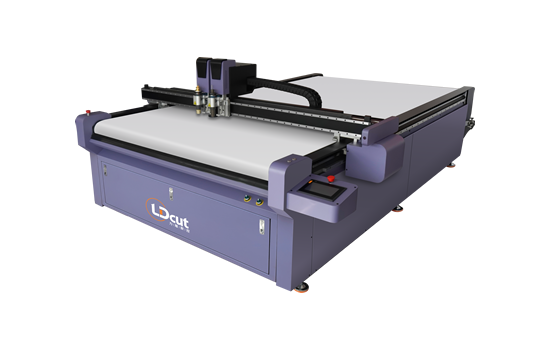

LDCUT L8

L Series

LDCUT L10

K Series

LDCUT K8

K Series

LDCUT K10

Typical production issues with traditional cutting equipment

Conventional cutting equipment often struggles with complex and irregular cutting tasks, resulting in inconsistent accuracy, increased material waste, and unstable product quality.

Manual operation or outdated equipment limits cutting speed, struggles with large-volume production demands, and negatively impacts delivery timelines and overall efficiency.

Single-function equipment lacks flexibility for different materials and cutting processes, leading to higher equipment investment and limited application scenarios.

Production relies heavily on skilled operators, resulting in high labor costs, inconsistent efficiency, and increased risks in long-term manufacturing stability.

Production efficiency revolution with innovative technology

The X and Y axes use German-imported ground racks, while the Z axis adopts an imported ground ball screw, ensuring micron-level positioning accuracy and reducing material waste by over 30%.

Say goodbye to expensive dies. Our digital knife cutting system with optimized motion control supports continuous feeding and cutting, ideal for short-run and mass production with 300% higher efficiency.

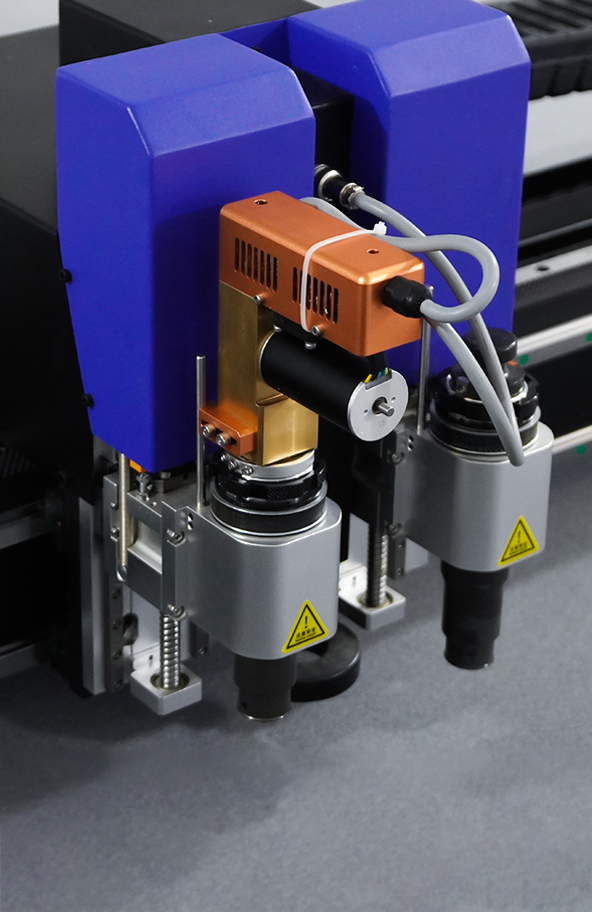

Multiple tool heads support quick tool-free replacement within 3 minutes, enabling full-cut, kiss-cut and more, compatible with PVC, KT board, cardstock, films and other materials.

An intelligent vision positioning system enables one-click scanning and automatic cutting, reducing manual intervention and lowering labor dependence by up to 40%.

LDcut high-speed conveyor belt irregular cutting machine integrates multiple cutting-edge technologies, delivering an unparalleled cutting experience

Bed undergoes welding, tempering, quenching treatment, high-precision gantry milling one-time forming, ensuring long-term stable operation

X and Y axes use German imported ground racks, Z axis uses imported ground ball screws, ensuring high-precision positioning and motion

High-definition camera, one-click scanning, intelligent positioning edge tracking cutting, with automatic feeding function, achieving automated production

Aircraft aluminum plate with zonal vacuum to fix materials, high load capacity, strong suction, ensuring material stability without displacement during cutting

Replaceable tool heads, achieving full-cut, semi-cut and other processes, meeting different material and cutting needs

Intelligent software enables easy operation, supports dxf, plt, jpg, tif formats, automatically completes feeding and cutting of oversized and multiple files for roll materials

Precision design, exceptional performance, meeting all your cutting needs

Drive System

Leadshine Brushless Full Servo

Table Structure

Rolling Felt Conveyor Table

Oscillation Frequency

18000 rpm

Camera Resolution

0.025 mm

Idle Travel Speed

120m/min

Processing Accuracy

±0.01mm

Working Area

Offers 4 Standard Sizes

Vacuum Pump

7.5KW Vacuum Pump

.jpg)

Suitable for multiple industries, meeting various complex cutting needs

With different blades, achieves processing of various materials. Can process KT board, foam board, corrugated cardboard, acoustic foam and other material cutting.

Through rapid blade movement, achieves material cutting processing, can process PP paper, adhesive, reflective materials, car stickers, ABS plastic, thin plastic, rubber cloth, imitation leather, KT board, PVC foam board, cardstock, soft glass, canvas, photo cloth and other materials.

Can process soft glass, PVC, honeycomb board, KT board, corrugated cardboard, vertical corrugated board, gray board and other materials for grooving and folding.

Through circular wheels rolling over material, creates creasing effects on material, processes corrugated cardboard, cardstock, corrugated plastic board and other materials for creasing and folding.

Achieves cutting through only the upper layer without cutting the lower layer material, mainly used for car stickers, adhesive labels, PP adhesive, color-white-color and other materials for semi-cut processing.

Intelligent storage of multiple material cutting solutions, intelligent fully automatic feeding system, quickly and accurately achieves intelligent cutting of various materials.

Diverse professional tool heads, meeting precision cutting needs for various materials

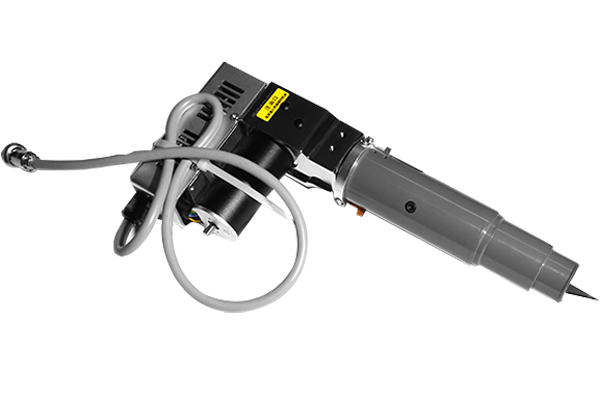

Oscillating Tool. High-frequency vibration cutting technology, suitable for precise cutting of thick materials, smooth cut without burrs

Drag Cutting Tool. Suitable for precise cutting of thin materials, 360-degree free rotation, achieving complex pattern cutting

Creasing cutting tool. Professional creasing tool, providing precise creases for cardboard, cardstock and other materials, improving packaging forming quality

Kiss cut tool. Precise kiss-cut technology, cuts only surface material without damaging backing paper, suitable for precise separation of multi-layer materials

V-cutting tool. V-cut technology, creates V-grooves on material surface, facilitating folding and forming, especially suitable for thick boards

LDcut High-Speed Conveyor Belt Irregular Cutting Machine supports quick change of all tool heads, no tools needed, switching completed within 3 minutes

Over 3000 global enterprises choose LDcut high-speed conveyor belt irregular cutting machine to improve production efficiency

Over 3,000 global enterprises trust LDcut

3,000+

Global Enterprises

80+

Countries & Regions

15+

Industries Served

22 Years of manufacturing legacy. 5S Standards. Zero Compromise.

LDcut delivers consistent performance for your production.

1 year warranty starts from CE label manufacturing date except the knife and rolling Felt.

Complete installation video and user manual helps you install the machine more efficiently.

Professional engineer team can speak English and respond within 1 hour, with 24/7 emergency assistance available for all production needs.

Comprehensive training on machine operation and software use from setup to production. We will handle all after-sales support—so you can focus on growing your business.

1 year warranty starts from CE label manufacturing date except the knife and rolling Felt.

Complete installation video and user manual helps you install the machine more efficiently.

Professional engineer team can speak English and respond within 1 hour, with 24/7 emergency assistance available for all production needs.

Comprehensive training on machine operation and software use from setup to production. We will handle all after-sales support—so you can focus on growing your business.

Fill out the form below, our professional consultants will provide customized solutions and quotes

Fill out the form to get customized solutions and technical support

Professional technical consultants one-on-one communication to understand your specific needs

Provide precise quotation solutions based on your materials and production needs

Respond to your inquiry within 24 hours, providing professional solutions

Comprehensive after-sales service system ensuring stable equipment operation